Ansi Asq Z1 9 2008 Pdf Download

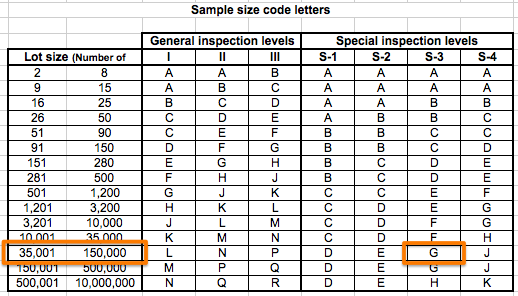

Acceptance sampling Wikipedia. Acceptance sampling uses statistical sampling to determine whether to accept or reject a production lot of material. It has been a common quality control technique used in industry. It is usually done as products leaves the factory, or in some cases even within the factory. Most often a producer supplies a consumer a number of items and a decision to accept or reject the items is made by determining the number of defective items in a sample from the lot. The lot is accepted if the number of defects falls below where the acceptance number or otherwise the lot is rejected. A wide variety of acceptance sampling plans are available. HistoryeditAcceptance sampling procedures became common during World War II. Sampling plans, such as MIL STD 1. Harold F. Dodge and others and became frequently used as standards. More recently, quality assurance broadened the scope beyond final inspection to include all aspects of manufacturing. Broader quality management systems include methodologies such as statistical process control, HACCP, six sigma, and ISO 9. Some use of acceptance sampling still remains. RationaleeditSampling provides one rational means of verification that a production lot conforms with the requirements of technical specifications. Rather than evaluating all items, a specified sample is taken, inspected or tested, and a decision is made about accepting or rejecting the entire production lot. Plans have known risks an acceptable quality limit AQL and a rejectable quality level, such as lot tolerance percent defective LTDP, are part of the operating characteristic curve of the sampling plan. Intelli Remote Pc Server Crack on this page. These are primarily statistical risks and do not necessarily imply that defective product is intentionally being made or accepted. Plans can have a known average outgoing quality limit AOQL. Acceptance sampling for attributeseditA single sampling plan for attributes is a statistical method by which the lot is accepted or rejected on the basis of one sample. Suppose that we have a lot of size Mdisplaystyle M a random sample of size Nlt Mdisplaystyle Nlt M is selected from the lot and an acceptance number Bdisplaystyle B is determined. If it is found the number of nonconforming is less than or equal to Bdisplaystyle B, the lot is accepted and if the number of nonconforming is greater than Bdisplaystyle B, the lot is not accepted. The design of a single sampling plan requires the selection of the sample size Ndisplaystyle N and the acceptance number Bdisplaystyle B. MIL STD 1. 05 was a United States defense standard that provided procedures and tables for sampling by attributes pass or fail characteristic. MIL STD 1. 05. E was cancelled in 1. ANSIASQ Z1. 4, Sampling Procedures and Tables for Inspection by Attributes. A Certified Quality Engineer understands the principles of product service quality evaluation control. Become an ASQ full member to get up to 150 off. Improvement driven by data is the best kind of tool to be used in business today. At QPS, we offer various tools to support ASQ certification, Minitab and Six Sigma. Military Handbooks and Standards along with NASA and Nuclear Regulatory Commission documents pertaining to reliability issues are here for quick search and download. Listing of standards covering attribute and variables acceptance sampling plans inclusing military, ANSI, and ISO standards. Several levels of inspection are provided and can be indexed to several AQLs. The sample size is specified and the basis for acceptance or rejection number of defects is provided. Variables sampling planeditWhen a measured characteristic produces a number, other sampling plans, such as those based on MIL STD 4. AMSC_homepagebanner.jpg' alt='Ansi Asq Z1 9 2008 Pdf Download' title='Ansi Asq Z1 9 2008 Pdf Download' />Acceptance sampling uses statistical sampling to determine whether to accept or reject a production lot of material. It has been a common quality control technique. Ansi Asq Z1 9 2008 Pdf Download' title='Ansi Asq Z1 9 2008 Pdf Download' /> Compared with attribute sampling plans, these often use a smaller sample size for the same indexed AQL. See alsoeditReferenceseditPyzdek, T, Quality Engineering Handbook, 2. ISBN 0 8. 24. 7 4. Godfrey, A. B., Jurans Quality Handbook, 1. ISBN 0. 07. 03. 40. XSqueglia, N L, Zero Acceptance Number Sampling Plans, Fifth Edition, ASQ Press, ISBN 9. ASQ standardseditSampling Procedures and Tables for Inspection by Variables for Percent Nonconforming, ANSIASQ Z1. Sampling Procedures and Tables for Inspection by Attributes, ANSIASQ Z1. ASTM standardseditASTM E1. Standard Practice for Probability Sampling Of Materials. ASTM E1. 22 Standard Practice for Calculating Sample Size to Estimate, With a Specified Tolerable Error, the Average for Characteristic of a Lot or Process. ASTM E1. 41 Standard Practice for Acceptance of Evidence Based on the Results of Probability Sampling. ASTM E1. 40. 2 Standard Terminology Relating to Sampling. ASTM E1. 99. 4 Standard Practice for Use of Process Oriented AOQL and LTPD Sampling Plans. ASTM E2. 23. 4 Standard Practice for Sampling a Stream of Product by Attributes Indexedby AQLISO standardseditSampling procedures for inspection by attributes, ISO 2. JIS standardseditSampling procedures for inspection by attributes, JIS Z 9. External linkseditA subscription fee is required to use the calculators. The free calculations have locked features. El Otro Lado De La Cama Torrent English.

Compared with attribute sampling plans, these often use a smaller sample size for the same indexed AQL. See alsoeditReferenceseditPyzdek, T, Quality Engineering Handbook, 2. ISBN 0 8. 24. 7 4. Godfrey, A. B., Jurans Quality Handbook, 1. ISBN 0. 07. 03. 40. XSqueglia, N L, Zero Acceptance Number Sampling Plans, Fifth Edition, ASQ Press, ISBN 9. ASQ standardseditSampling Procedures and Tables for Inspection by Variables for Percent Nonconforming, ANSIASQ Z1. Sampling Procedures and Tables for Inspection by Attributes, ANSIASQ Z1. ASTM standardseditASTM E1. Standard Practice for Probability Sampling Of Materials. ASTM E1. 22 Standard Practice for Calculating Sample Size to Estimate, With a Specified Tolerable Error, the Average for Characteristic of a Lot or Process. ASTM E1. 41 Standard Practice for Acceptance of Evidence Based on the Results of Probability Sampling. ASTM E1. 40. 2 Standard Terminology Relating to Sampling. ASTM E1. 99. 4 Standard Practice for Use of Process Oriented AOQL and LTPD Sampling Plans. ASTM E2. 23. 4 Standard Practice for Sampling a Stream of Product by Attributes Indexedby AQLISO standardseditSampling procedures for inspection by attributes, ISO 2. JIS standardseditSampling procedures for inspection by attributes, JIS Z 9. External linkseditA subscription fee is required to use the calculators. The free calculations have locked features. El Otro Lado De La Cama Torrent English.